Preconditions

Before a revision can be executed:

- The deck does not have major defects, meaning no vital parts are missing, the tape counter, VU-meters and all motors are functional, the deck is able to playback and record.

- In case the pinch roller rubber has melted or perished and no tape transport is possible, the VU-meters should react to a source signal. The capstan(s) should rotate when the tape tensioner(s) are lifted.

- If earlier improper repairs or modifications have been executed, additional costs may apply to correct these repairs or modifications.

Revision activities

Depending on the brand and type of the tape deck a standard and/or extended revision can be offered.

In case the tape heads have a significant wear groove a so called relapping of the heads might be necessary to obtain optimal playback and recording results. Such heads accumalate oxide deposits quickly creating drop outs during playback and recording. A relap service restores the original head shape by removing material around the wear groove until the head surface is smooth again. A relap service requires specific tools and especially specialist knowledge. It is the only activity in a revision which I don’t do myself, but is done by external experts.

Standard revision activities – varies depending on tape deck brand and type:

- Overall external/internal inspection and basic measurements.

- Installing new manufactured high quality pinch roller(s) – NO rubber tire(s) – and new capstan drive belt (if applicable).

- Cleaning switches with DeoxIT spray.

- Desoldering of potentiometers for chemical and ultrasonic cleaning and lubrication. NO sticky contact cleaners.

- Tape decks with DC capstan motor: cleaning of commutator (carbon dust, polishing shaft en lubrication of motor bearings

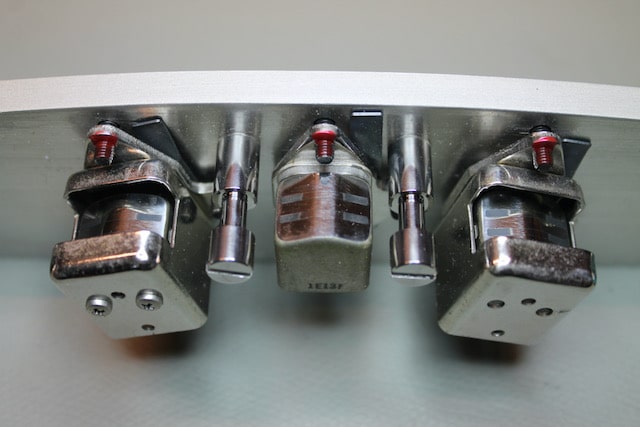

- Full disassembly of tape tensioners: ultrasonic cleaning, lubrication (white lithium grease/synthetic oil), renewing damping fluid (if applicable).

- Installing new micro switches (Omron) in tape tensioners.

- Lubrication of pinch roller linkage with white lithium grease.

- Replacement of power cable including earthing of metal chassis (Class 1 appliance).

- Adjustment of reel brakes and reel motor torques (according service manual)

- Adjustment of capstan motor speed (according service manual)

- Wow & flutter check (playback speed stability and fluctuations) with calibration tape.

- Head azimuth adjustment with calibration tape.

- Adjustment of playback volume and EQ with calibration tape.

- Adjustment of record volume, bias and EQ on tape of choice: Maxell XLI, RTM LPR35 or LPR90 (other tape types on request)

- Measurements: frequency response, distortion, W&F, S/N ratio

Extended revision activities – varies depending on tape deck brand and type::

All standard revision activities and additionally:

- Complete disassembly of mechanics for cleaning/degreasing of parts in ultrasonic cleaner.

- Replacement of electrolytic capacitors on alle PCB’s by:

- Elna Silmic II or Nichicon for audio circuits

- WIMA or Panasonic film for input capacitors!

- WIMA film for electrolytic caps < 1µF:

- Panasonic FR or FC series for all other electrolytic capacitors

- PCB cleaning with 99% iso-propanol (removal of old flux residues)

- Renewing thermal conducting paste for components on heat-sink.

- Disassembly of double gang potentiometers meters to restore fluid L/R adjusment.

- Disassembly of AC reel motors, replacing oil sponges and lubrication of motor bearings.